The innovation for documenting the real wear time of orthopedic aids.

The success of the therapy with time-critical orthopedic aids is directly connected to the discipline the patient shows in wearing the respective aid. For the team treating a patient, it has almost been impossible up to now to measure a poor compliance in the case of a non-functioning orthopedic aid and to figure out why the aid is failing to function properly. Orthotimer is an electronic wearing time system that thoroughly documents the wearing time of the device for outpatients.

The heart of the orthotimer® system is a small dust and watertight microsensor (9x13x4.5mm) that can be easily integrated in all sorts of aids, for example, orthotic devices, shoes, insoles, prostheses, bandages, medical (compression) stalking, etc. Every sensor features a unique individual ID number and can be automatically connected to the patients registered in the database.

The microsensor is controlled with the wireless reading device and the saved wearing time dates are transferred to the respective software. The reading device is connected with the computer via a USB plug.

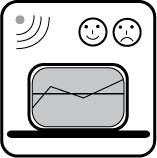

The software is used to control the microsensor as well as to perform the wear time analysis of the patient data. The wear time is presented in various charts. Depending on what the user would like, he/she can observe a total wear time overview or an individually selected range extract from the entire monitoring period of time. The readings are then aligned seamlessly next to each other in the software after each reading is taken in order to get an error-free picture of the overall wear time. With the function “Generate raw data“, the measurement data can be transferred into an Excel file and made further use of for scientific studies. With the “Report” function, you can generate a report of the patient’s wear time. This can then be made available to the patient and/or the doctor.

Orthotimer® has been especially developed for use in orthopedic aids. The system is already being made use of in many technical orthopedic operations, clinics, institutes, universities, doctoral practices, and within the technical orthopedic industry. The necessity of the compliance runs through all areas of technical orthopedics. The system is most particularly made use of i.e. in cases of scoliosis, diabetes, hip dysplasia, plagiocephaly, in phlebology, and for fractures.

Info: www.ispo2017.org

Info: www.ivo2015.com

Info: www.egrohweb.de

hosted by BioRegio STERN Management GmbH

Haus der Wirtschaft, Stuttgart, Germany

Start: Tuesday, Apr 29 2014 9:30 AM

End: Tuesday, Apr 29 2014 4:30 PM

Info: http://www.bioregio-stern.de/de

To be seen on 08.-10.05.2014 at the SOSORT in Wiesbaden.

Info: http://sosort2014.com

Info: http://ot-world.com

Info: http://www.diabeteskongress.de/

Info: http://www.dkou.org/dkou2014

Orthotimer was mentioned in the journal "Orthopädie Schuhtechnik" (orthopedic footwear technology) in "news for analysis and manufacturing.".

Article in "Orthopädie Schuhtechnik" 08/07/2014 (PDF-Download)

Article in "Medizin-Technischer-Dialog" (PDF-Download)

How should a measurement and evaluation system for technical orthopedic shoe operations be set up in order to obtain practical data from the individual living environment of patients? Exactly this is currently being examined by a pilot study featuring an interdisciplinary research team. The focus of the study is being placed on providing the proper shoes for diabetic foot syndrome, as the quality of care and the success of the therapy is considerably dependent upon the use of aids in one’s everyday life.

This is made use of for compliance measurement of the test subjects.

Source: Orthopädieschuhtechnik 12/2013

Matthias Roller spent a number of years working as a licensed orthopedic technician in an orthopedic clinic. This was followed by a 3 year sojourn in Boston, USA, where he served as a technical orthopedic consultant in the field of high performance sports and as a market developer. Back in Germany, he worked as a product manager for a company in the orthopedic industry. He then conducted his master’s studies in Neuro-Orthopedics – Disability Management in Austria.

In 2007, he founded the consulting firm Rollerwerk-Medical, which deals primarily with product development, development of medical concepts, and branch-specific consultation. He consults institutions and aid organizations in questions of rehabilitation and is part of the board of chairman for an NGO (www.mna-ev.org) that is constructing a rehab center in Albania.

Since the beginning of 2013, Matthias Roller has been researching the patient compliance of diabetes and scoliosis as a PhD candidate at the University of Groningen, (UMCG).

With growth-guiding, corrective, and relieving orthopedic aids or as part of studies about various aids for improving their expressiveness. The system is also made use of in the field of product development for measuring the microclimate and the wear time.

The minimal size of the sensor allows it to be used in all sorts of aids. There are many options for integrating the sensor into the aid. The many orthopedic aids demand various procedures for integration such as, i.e. lathering, pasting, or having the sensor be sewn into them. The microsensor can also be directly laminated into the aid when necessary.

If stronger temperatures are generated (< 60°C), as is the case with the deep-drawing of polyethylene and polypropylene, it is recommended that a sensor dummy be made use of, which is then exchanged with the original microsensor after the deep-drawing process and is attached to the aid.

We recommend that the thermosensor be integrated as closely to the body as possible. A direct skin contact between the patient and the sensor is not necessary. It can be simply placed under a thin padding material or some sort of tape. You should ensure that the padding material above the microsensor isn’t too thick so that no isolation effect takes place between the patients and sensor, otherwise the material could distort the measurement data.

The sensor should be placed on pressure points in the orthopedic aid so that this point is always close to the body.

The sensor needs to measure the interior climate of the aid as close as possible and thus, it should not be placed too closely to the fringes or on the edge of the aid so as not to be influenced too much by the exterior temperature. It should be possible to receive a clear temperature differentiation between the wearing temperature and the exterior temperature.

Through the compact size of the microsensor, there are almost no limits to its use. The orthotimer® is very often built right into aids that have a relieving, corrective, stabilizing and compromising effect and with which the timeframe of effectiveness is limited. These are most especially scoliosis ortheses, diabetic shoes, inlays and walkers, medical (compression) stockings, hip dysplasia ortheses, head ortheses, and fracture ortheses. They are often also made general use of for studies on the compliance of test subjects to ensure the significance and permanence of the study.

Matthias Roller

Trogenstr.6

D-72336 Balingen

fon: +49-(0)7433/ 260 84 86

fax: +49-(0)7433/ 260 84 88

e-mail: info@orthotimer.com

rollerwerk medical engineering & consulting

Matthias Roller

Trogenstr.6

D-72336 Balingen

fon: +49-(0)7433/ 260 84 86

fax: +49-(0)7433/ 260 84 88

e-mail: info@rollerwerk-medical.com

Ust-Id-Nr DE253471681

St-Nr 53327/28016

Responsible for content: Matthias Roller

Wording & Graphics: Denise Seemann, designtreu

Website: Michael König, TreeDEV